Applications

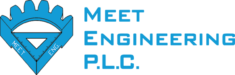

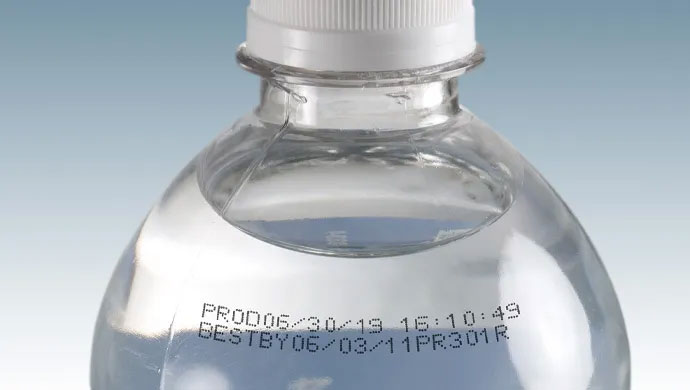

Printing on PET Bottles

Industrial Coding and Marking Solutions for PET Plastic Bottle

Printing Polyethylene terephthalate (PET) has long been used as a liquid container in the carbonated soft drink, bottled water, energy and fruit drinks markets due to its inherent properties of strength, flexibility and transparency. Additionally, PET bottles are gaining popularity over materials like HDPE for packaging consumer products such as shampoo. Videojets application expertise in PET marking spans many years, including deep knowledge of trends such as lightweighting. PET bottles are most commonly marked using Continuous Inkjet (CIJ) and laser printing solutions. Videojet offers a number of unique ink formulations that provide quality ink jet codes on PET, and laser systems for high resolution, permanent marks.

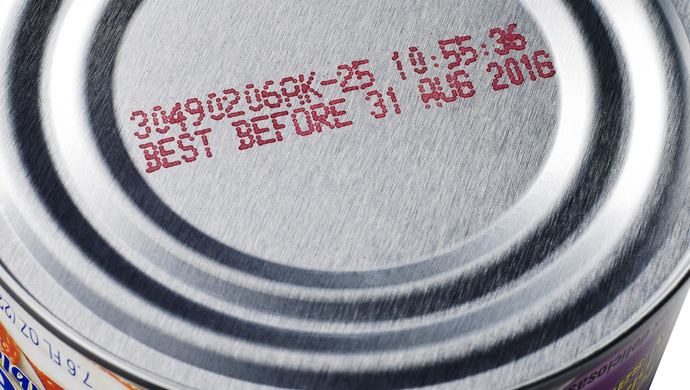

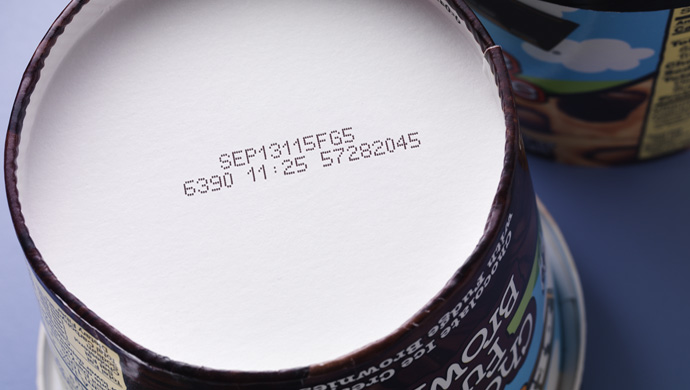

Printing on Metal and Aluminum Cans

Industrial Coding and Marking Solutions for Metal and Aluminum Can

Printing Aluminum canning operations are among the fastest packaging lines in the world and require specialized equipment. Metal cans are widely used with shelf-stable foods and when products require retorting, specialized color-change inks serve as a visual quality control indicator that the products have successfully completed the process. Videojet offers printing solutions to match the demands of these applications, including ultra high speed printer options. Coupled with a comprehensive range of high speed and thermochromic inks, Videojet brings over 40 years of canning application expertise to our customers. In addition, high powered fiber lasers offer unique mark options for specific metal canning applications.

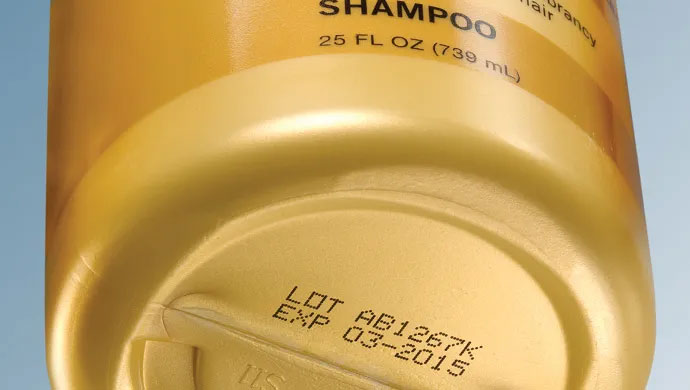

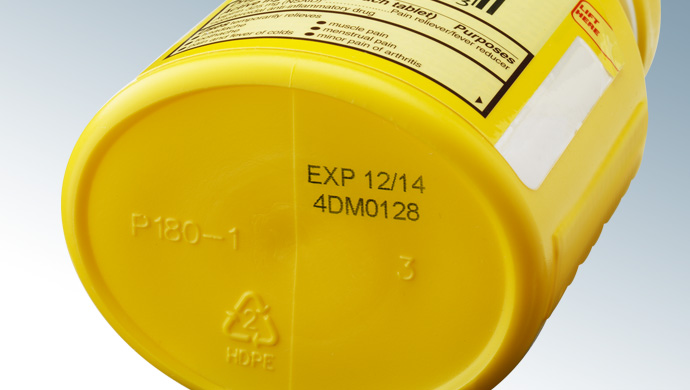

Printing on Plastic Rigid Containers

Industrial Coding and Marking Solutions for Printing on Rigid Containers

Polyethylene (PE) and High-density polyethylene (HDPE) are among the most common plastics used for rigid packaging. With relatively low surface energy, these plastics can be challenging to mark. Mold release agents, if present, should also be considered when selecting the right marking solution. A variety of Videojet solutions are available depending on the desired mark effect. Our selection of inks for Continuous Inkjet (CIJ) printers provide quality marks on a wide range of plastics, including high adhesion inks and oil penetrating inks specifically for plastics. Laser systems, which deliver permanent but less-noticeable marks, are also an option. Videojet offers a wide laser range including CO2, Fiber and UV to best match laser wavelength with the plastic material.

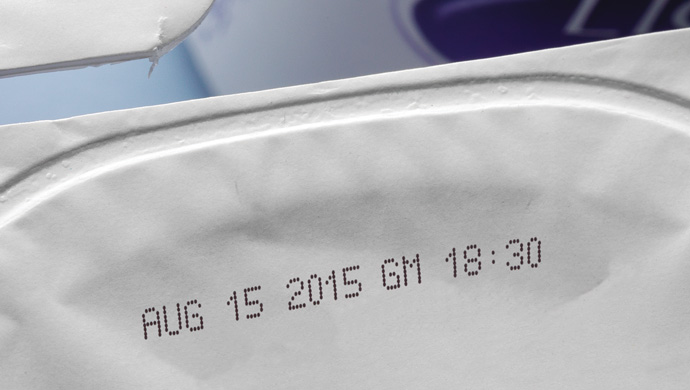

Printing on Flexible Films and Foils

Industrial Coding and Marking Solutions for Flexible Packaging Printing

Low density polyethylene (LDPE) and flexible metallized films are widely used for confectionary and salty snacks packaging. Flexible packaging is the fastest growing packaging type driven by innovations including zippers, gussets and windows. Flexible packaging is also popular because of enhanced shelf appeal, portion control packaging and lower transportation costs. Videojet Thermal Transfer Overprinters (TTO) deliver high resolution, variable data marks on a variety of film stocks with a selection of ribbon colors for added contrast. Continuous Inkjet (CIJ) printers can apply codes before or after the film is formed and packaged, offering integration options.

Printing on glass bottles and containers

Glass bottles and containers remain a popular packaging option for a number of reasons including product differentiation and identification of a premium product. In addition, its reuse (returnable bottles) and recyclability make it an environmentally good choice. Glass bottles are popular for a variety of food and beverage products including those that require a strong protection barrier. Videojet offers a broad range of Continuous Inkjet (CIJ) and laser solutions for marking onto glass. Pigmented inks are available for high contrast codes on dark colored glass bottles or clear bottles containing dark liquids. A unique ink formulation provides a high quality inkjet code that can also be easily removed for returnable bottle applications. Videojet laser systems deliver high resolution, permanent marks on nearly any type of glass container.

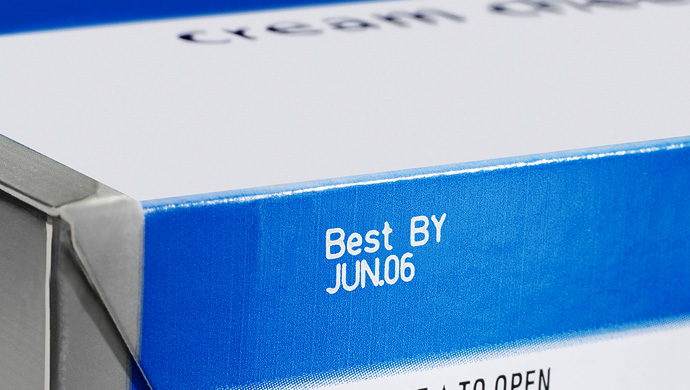

Printing on Paperboard Packaging

Industrial Coding and Marking Solutions for Printing on Paperboard Containers

Paperboard packages offer versatility across a number of industries. Dry shelf-stable foods, cookies, pastas and cereals utilize this packaging option as well as secondary packaging for pharmaceutical and personal care products. Paperboard is often also used as primary packaging for industrial parts. Videojet offers a broad range of marking options depending on the application requirements. Solutions include everything from high speed Continuous Inkjet (CIJ) for fast production lines to laser for permanent, high resolution marking to Thermal Inket (TIJ) that delivers multiple code options including a selection of fonts, characters sizes and bar codes.

Printing and labeling on corrugate

Corrugate containers deliver versatility as a packaging solution for use in the shipping, warehouse, distribution and logistics markets. The high strength to weight ratio makes it an ideal option for these applications. Videojet offers solutions that provide options in character height, print resolution and bar code quality including label print and apply for high bar code read rates. Colored inks for Videojet large character ink jet printers can provide visually attractive brand information and product identification. Colors can also be used to print visual cues to identify particular sub-brands, distinguish between different grades of product, or to highlight product compliance with specific building codes or regulations.

Printing on retail-ready packaging

Retail ready packaging (RRP) is a high-growth segment of the food and consumer goods industry. The appeal of shelf-contained units is the ability to get products to shelf faster by removing the time needed to unpack product or set up displays. Coated cardboard creates its own set of marking challenges where typical solutions for printing on corrugate are not sufficient. For small and medium codes, the Videojet thermal ink jet (TIJ) with MEK-based inks adhere to coated cardboard surfaces, alternatively, laser systems can be used to ablate the surface, leaving behind high resolution codes. Labeling with Direct Apply™ is yet a third option which functions exceptionally well for trays and other low profile packaging

Printing on shrink wrap

Shrink wrap remains a widely used packaging option, allowing consumers to view the product while protecting it from outside factors such as air or contaminates. When used to bundle products, shrink wrap’s versatility for efficient shipping, storage and display offers advantages over traditional corrugate packaging. Videojet continuous ink jet (CIJ) printers are non-contact, offering advantages for shrink wrapped packages with oddly shaped or curved edges. Large character ink jet printers offer printheads and inks that enable printing on a wide range of porous and non-porous materials. Videojet print and apply labeling solutions can aid with high contrast bar codes for increased readability.

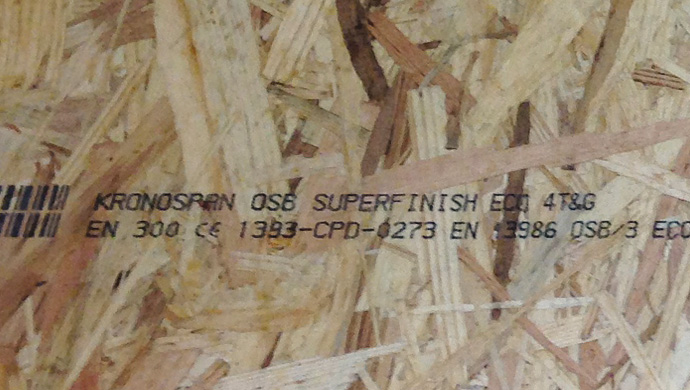

Printing on extrusions

Extrusion of industrial products can present a range of application and substrate dependent marking challenges. Lubricating oils, high temperatures, and other environmental factors such as dust requires a careful specification of coding solutions to avoid unplanned downtime. Videojet continuous inkjet (CIJ) printers offer exclusive technologies to help print clean, consistent codes, even in challenging production environments. We offer fast-dry, heat and oil-penetrating inks for optimal line performance. Our Code Assurance solutions can help simplify operator-to-printer interaction, and better equip operators to achieve the right code on the right product, time after time. Videojet laser solutions are virtually maintenance-free and provide crisp, permanent codes on a variety of extruded materials.

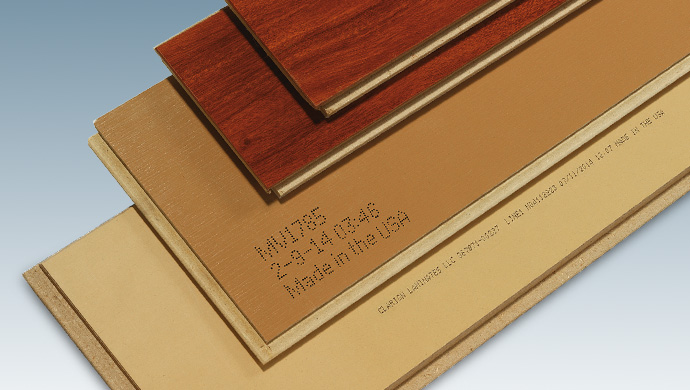

Printing on wood

Wood production environments are dusty and can experience significant seasonal temperature fluctuations. Products range from raw lumber used in construction to coated or varnished products for furniture, flooring and other finished items. Videojet large character inkjet printers offer a robust industrial design with micro-purge printhead technology for harsh production environments. Continuous inkjet (CIJ) printers deliver high contrast codes and offer the option of printing with pigmented inks including white, blue, red, and yellow for added visibility. Videojet solutions can be used to print a wide variety of data including moisture levels, panel grades, inspector ID information and other traceability data.

Printing on eggs

Focus on food safety is paramount for egg producers. The need to easily communicate important expiration and traceability data and helps ensure compliance with safety regulations. Evolving regulations, changes in consumer preferences, food safety concerns and retailer demands are all factors in this industry. Videojet has over 30 years of experience in egg marking applications with both food grade printers and PDA-approved inks. Videojet’s continuous inkjet (CIJ) solutions can help promote brands by printing directly on eggs, while improving coding quality to increase the convenience and appeal of egg products. In addition, Videojet has a range of solutions including CIJ and laser for printing high quality marks on paper, plastic or foam cartons.

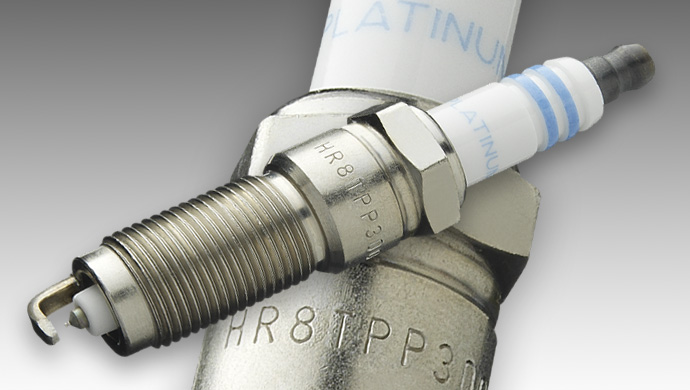

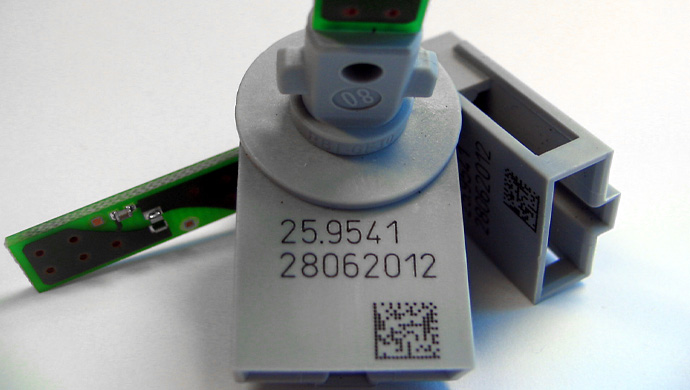

Printing on metal parts

Machined or formed metal parts can require a range of codes for either internal or external traceability. Working with a partner that offers a wide variety of coding solutions and integration expertise can be beneficial when specifying the optimal solutions for a range of material properties and application challenges. Laser and continuous ink jet (CIJ) remain two of the more common marking technologies for metal components. Videojet’s laser wavelength options provide greater flexibility in matching the given material. CIJ printers offer easy integration for printing on a wide variety of metals and are an ideal solution to print on curved or indented surfaces. Videojet also offers MIL SPEC inks to meet specific military and aerospace requirements.

Printing on plastic and rubber parts

Plastic and rubber parts vary in composition, color and elasticity. They include an array of substrates including polypropylene, polyurethanes, acrylonitrile butadiene styrene, and sometimes include slick plasticizers and other challenging components. With over 40 years of ink development experience, Videojet offers a range of high adhesion inks for even the most challenging substrates. Colored and pigmented inks provide high contrast codes on darker surfaces for easier readability, important for both internal manufacturing controls as well as external traceability. Videojet laser marking systems offer permanent marks for traceability throughout the product life cycle. A wide range of laser accessories including lenses and beam turning units help simplify line integration and maximize laser performance.